|

Design for

Manufacturing – Quick tables of Interconnection/Wire-bond

Basics

1. Electric Current vs. Wire Size

2. Basics of Board, Substrate, Package, Flex

3. Gold Plating

4. Trace Attributes

Layout

5. Bond-Pad size on Die vs. Wire Size

6. Die Mounting-Pad Size vs. Die Size

7. Better Trace Layout

8. Geometry re Trace-End

9. Obstacle Position, away from the 2nd bond-point

Process

10.

Assembly Process Concerns

11.

Eutectic Attach and Epoxy Attach

12.

Mistakes & Advice on Board Preparation

13.

Assembly Issues and Answers

14.

Bond Variables

15.

Wire-Bond Quality Data

16.

Glob Top Encapsulation

Advance concern: Wire Inductance

17.

Principles of Wire Parasitics

18.

Inductance of 2 Wires

19.

Wire Inductance Calculation, Simplified

20.

Wire Length for Inductance Concern

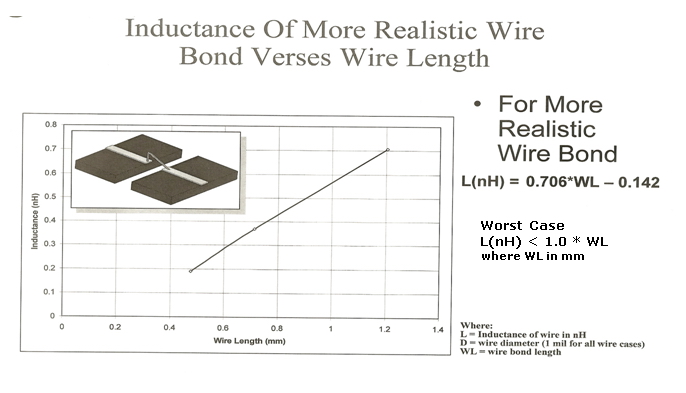

21. Wire Inductance

Table & Calculation, Realistic

1. Electric Current vs. Wire Size

|

Material

|

Wire dia,

mil

|

Max. Amp

|

|

Length < 40 mil

|

0.1” > Length > 40 mil

|

|

Gold

|

0.7

|

0.556

|

0.380

|

|

Gold

|

1.0

|

0.949

|

0.648

|

|

Alum

|

0.7

|

0.407

|

0.208

|

|

Alum

|

1.0

|

0.696

|

0.481

|

|

Alum

|

2.0

|

1.968

|

1.360

|

Calculation Info

|

Electrical

|

Alum

|

Gold

|

|

Specific Resistance, ρ

|

Ω

(mm

²)/ M

|

0.0278

|

0.0222

|

|

Specific conductance,

η = 1/ρ

|

M /

Ω (mm

²)

|

36

|

45

|

|

Maximum current in

DC amperes or rms AC ampers

I max = K d

³/²,

d =

wire dia. in

|

K

|

Length

< 40 mil

|

22,000

|

30,000

|

|

Length

> 40 mil

|

15,200

|

20,500

|

2. Basics of Board, Substrate, Package, Flex

|

|

Board,

FR-4 PCB

|

Substrate,

Thick Film

|

Packages,

Metal

|

Flex

|

|

Base Material

|

FR-4

(Epoxy)

|

Al2O3

(Ceramics)

|

Kovar,

Fe52Ni29Co18

|

Polyimide (Kapton);

Polyester (Mylar)

|

|

Conductor

|

Cu + Ni +

Au plating

|

Au, PdAg, PdPtAg, Cu

|

|

Cu + Ni +

Au plating

|

|

Dielectrics

|

Epoxy, FR-4

|

Glass-Ceramics

|

Glass-Ceramics

|

Kapton;

Mylar

|

|

Fabrication

Processes

|

Photolithography, etch, collate, sheets, laminate, Drill vias, plate

|

Sequentially print, dry, afire conductor, dielectric, and resistor pastes

|

machining

|

Photolithography, etch, collate, sheets, laminate, Drill vias, plate

|

|

Line width,

um, min

|

75

|

125

|

|

75

|

|

Via dia, um min

|

200

|

250

|

|

<200

|

|

Conductor Resistance, mW/sq

|

0.15~1

|

2-100

|

|

0.15~1

|

|

CTE (or TCE), ppm/8C

|

4~16

|

4~7.5

|

5.5

|

18

|

|

Thermal conductivity,

W/m@K

|

low

|

Much higher

|

16.5 W/m.C @25C;

17.6 W/m.C

@ 100C

|

low

|

|

Tolerance to temp extremes

|

Low

|

High

|

|

Low

|

|

Relative cost

|

Low

|

High

|

High

|

Low

|

3 Gold Plating

3.1 Over copper on Board, IPC-4552,

|

1st level

|

Ni

|

150 ~ 200 micro inches nickel over copper clad PCBs

|

|

2nd level

|

Au

|

5 ~ 15 micro inches malleable, 99.99% pure gold, over nickel.

|

3.2 Commercial Plastic Package, e.g. PBGA

|

1st level

|

Ni

|

50 micro inches min.

|

|

2nd level

|

Au

|

20 micro inches min.

|

3.3 Ceramic Package, e.g. Kyocera’s C-DIP

|

1st level

|

Ni

|

60 ~ 350 micro inches

|

|

2nd level

|

Au

|

60 ~ 225 micro inches

|

3.4 Substrate, Thick film

|

Au

|

400 micro inches, Stencil printed

|

4. Trace Attributes

|

Material

|

Die

Bondability

|

Wire

bondability

|

Solder-ability

|

Corrosion

resistance

|

|

Eutectic

|

Epoxy

|

Gold

|

Alum

|

|

Au

|

good

|

excellent

|

excellent

|

good

|

per solder type

|

excellent

|

|

PdAu

|

NG

(no good)

|

excellent

|

Fair

to poor

|

fair

|

good

|

excellent

|

|

PdAg

|

NG

|

excellent

|

good

|

good

|

good

|

good

|

|

PdPtAg

|

NG

|

excellent

|

good

|

good

|

good

|

good

|

|

Cu

|

NG

|

excellent

|

fair

|

fair

|

excellent

|

poor

|

|

Ni

|

NG

|

excellent

|

NG

|

good

|

NG

|

excellent

|

|

W

|

NG

|

excellent

|

NG

|

NG

|

NG

|

good

|

5. Bond-Pad size on Die vs. Wire Size

|

Pad Size,

mil x mil

|

Min.Pad-Pitch, mil

|

Wire dia, mil

|

|

Side

|

Corner

|

|

4 x 4

|

5

|

6

|

>=1.0

|

|

3 x3

|

4

|

5

|

1.0

|

|

2.6 x 3

|

3.5

|

4.5

|

1.0 or 0.7

|

|

2.0 x 2.4

|

2.5

|

3.5

|

0.7

|

6. Die-Mounting-Pad Size vs. Die Size

Die-mount-pad (A x B) vs. Die size (dl x w)

|

Comply with

MIL-STD-883

|

A x B > =

|

(dl + 8 x 2 mil) x (w + 8 x 2 mil)

|

|

Don’t care

MIL-STD-883

|

A x B =

|

dl x dw

|

7. Better Trace Layout

Trace-end Layout

|

Uniform & even

|

staggered

|

hoe

|

|

Better, if

|

They are parallel to

the bond-pad of each side of die

|

|

Use stagger way

to narrow the trace pitch

|

|

Apply the hoe shape

at the trace end

|

|

Avoid

|

To wire trace and die-pad in big angle,

e.g. corner wires and angle wires

|

Warning: The corner wires of wide angle might cause the electric

short on the chip surface.

8. Geometry re Trace-End

8.1 Trace-end Width

|

Min. width, mil

|

Comfort width, mil

|

|

2.6 ~ 3

(The flatness of

profile is difficult.)

|

5~8

|

8.2 Trace-end Position

|

Wire dia., mil

|

Distance away from

chip, mil

|

Comfortable distance

away from chip,

mil

|

|

Max.

|

Min.

|

|

Forward

Bonding

|

Reverse

Bonding

|

Level difference

(1st/2nd bond)

0 mil

|

Level difference

6 mil

|

Level

difference 11 mil

|

|

0.7

|

90

|

150

|

8

|

12

|

25

|

35 ~ 55

|

|

1

|

150

|

210

|

10

|

15

|

35

|

40 ~ 70

|

9. Obstacle Position, away from the 2nd bond-point

Minimum Obstacle Distance away from the 2nd

bond-point

|

|

H, mil

|

W, mil

|

|

20

|

40

|

|

40

|

45

|

|

60

|

50

|

|

80

|

55

|

|

100

|

65

|

|

10. Assembly Process

Concerns

Remember these

|

Sequence

|

Go first with high temp process; then

follow with low temp process.

|

|

Avoid

|

“Piggyback” mounting

|

|

Use tin-lead solder and flux in hybrid circuit

that has wire-bond.

|

|

Have components on the back side of bond area before bonding.

|

|

Do wedge bond with Alum or Gold wire

|

It’s more tolerable to the variance of surface condition.

|

|

Require max. current

|

Bond two wires on pad instead of one, if pad is large, e.g. diode.

|

11. Eutectic attach and Epoxy attach

Comparison of Alloy

and Epoxy Attachment Methods

|

Eutectic/Alloy Attach

|

Epoxy Attach

|

|

Provide electrically conductive path

|

Can be electric conductive or insulative pending on epoxy used

|

|

High thermal conductivity

|

Low for insulative epoxy; better with silver-filled epoxy

|

|

High material cost

|

Low material cost

|

|

High temp process

|

Low temp process

|

|

No outgassing

|

Outgassing; requires vacuum control sometimes

|

|

Generally require fluxing and special cleaning

|

No flux required

|

|

Can be rigid and brittle, causing cracking of large die

|

Inherently flexible, provide stress

relief

|

|

No bleed-out

|

May bleed-out during cure

|

12. Mistakes & Advice On Board Preparation

12.1 Common

mistakes

|

|

Description

|

Potential trouble

|

Last solution if the

trouble happens

|

|

1

|

Form a big wire angle between the corner bond-pads & traces

|

Wire short on die surface

|

Offset die placement;

Use 0.7 mil wire

|

|

2

|

Limited gap between die & trace

|

Can’t form a wire loop

|

Use 0.7 mil wire

|

|

3

|

Small bond-pad pitch

|

Can’t bond with 1 mil;

Short on chip surface

|

Use 0.7 mil wire

|

|

4

|

Small bond-pad size

|

Oversize with 1 mil

|

Use 0.7 mil wire

|

12.2 All kinds of mistakes

|

|

Macro-checking

|

Microscopic Observation

|

Create troubles in

Percentage rate

|

Advice

|

|

1

|

Board is too thin

|

board warpage or camber

|

wire-bond non-stick

|

Thicker board

|

|

damping during bonding

|

|

2

|

Board size is too large

|

---

|

No flexibility of module(s)

|

Max < 3” ~4” Square;

Preferred, about 1.5” x 1”.

|

|

Circuit is too big and rigid

|

|

3

|

Bad trace quality

|

Bare copper surface

|

---

|

Wire-bond Non-stick

|

Gold/ Ni plated over

Copper

|

|

Oxidized surface

|

Scattered dark spots

or dark cloudy

|

|

Foreign matter

contamination

|

Oily or dull surface

|

|

Narrow trace

|

Cross-section is in round profile

rather than flat.

|

|

4

|

Die-mount-pad

|

Solder residue

|

Flux migrate and spread around

|

Wire-bond Non-stick

|

Don’t touch the die-mount -pad.

|

|

Large thru-holes in pad area

|

Force die-placement shifted from the

designed position

|

wire-bond difficulty in terms of

wire-length or corner wire bonding

|

Hole dia < 1/3 die width

|

|

5

|

Other components on board

|

Components are too high or too close

to the bond-area

|

wire-bond difficulty or impossible

|

Check with wire-bond specialist in-advance

|

|

6

|

Solder components on top surface

|

Chemical residue spread all over the

surface

|

Wire-bond

Non-stick

|

Use conductive epoxy

instead of soldering

|

|

7

|

Residue of solder flux, Chemical

cleaner, metal chips, foreign matters

|

Micro-particles or chemical

residue on surface

|

Wire-bond non-stick

|

Don’t do washing, flushing, wiping.

|

|

8

|

Mechanical polished (shiny) board

surface

|

Mountains and valleys surface with

dirt hide in grooves

|

Wire-bond non-stick

|

Should never do sanding, polishing.

|

|

9

|

Solder spots on back surface

|

Create minor gap between board and

work-holder

|

Clamping issue or even

wire-bond non-stick

|

Inform wire-bond specialist in-advance to modify the clamping fixture

|

|

Damping during bonding

|

|

10

|

Jumper wires on back surface

|

Create minor gap between board back

surface and work-holder

|

Clamping issue or even

wire-bond non-stick

|

Inform wire-bond specialist

in-advance to modify the clamping fixture.

Place jumper wires on top surface.

|

|

Damping during bonding

|

13. Assembly Issues and

Answers

Issues

Answers

|

1.

Epoxy Die-Attach

•

Many cavities show up

•

Hand touches units

during inspection

|

•

Cure epoxy in a higher temp, short time.

•

Design a mechanism that can let you take units out easily.

•

Design a carrier.

|

|

2.

Epoxy seal, e.g. lid-attach, RingFrame-attach

•

Bad appearance and low thru-put

|

•

Design the process fixtures.

•

Improve programming.

|

|

3.

Eutectic Die-Attach

•

Can’t hold the substrate.

•

Keep raising the temp setting.

|

•

Source work-holder from Internet.

•

Design the fixture.

•

Improve the work-holder surface.

|

|

4.

Solder Attach, Lead-frame, < 40 Leads

•

Bad solder joints or low thru-put.

•

Ineffective cleaning

|

•

Develop process tools or manual machine.

•

Choose a solder paste of water soluble flux.

•

Develop the process tools.

•

Use DI water.

|

|

5.

Hermetic seal, with furnace.

•

Failed at visual inspection or

bubble

test.

|

•

Control the clamping force with gram gage.

•

Improve the thermal flow of vehicle.

•

Tune the temp profile.

|

|

6.

Wedge bond

•

Non-stick

•

Break at heel

•

Bad bond accuracy.

•

Cratering

|

•

Tune the bond parameters. See Graphics A&B.

•

Tighten the bonding wedge.

•

Improve substrate clamping.

•

Clean material surface. See Graphics A&B.

•

Choose a different wedge.

•

Low the power. See Graphics A&B.

•

Minimize the back bend of looping.

•

Improve programming, machine calibration.

•

Lower the power. See Graphics A&B.

•

Adjust the approaching speed.

See Graphics

A&B.

•

Improve clamping.

|

|

7.

Ball bond

•

Ball bond size is larger.

•

Weak transition from the stitch bond to the wire.

|

•

Reduced Free-Air-Ball size or shorten the distance between wand and

capillary.

•

Improve wand mechanism.

•

Choose a different capillary.

•

Lower the bond force.

|

14.

Bond

Variables

|

|

Ball bond

|

Wedge bond

|

|

Welding parameters

|

Power, Force, Time, EFO,

Temperature,

|

Power, Force, Time, Temperature

|

|

Looping parameters

|

Wire length,

|

Wire Clamp open/close position

|

|

Elevation between bonds

|

Forward bond, reverse bond

|

|

Wire straightness, sagging

|

Wire length, elevation, straightness, sagging

|

|

Other parameters

|

Crescent of 2nd bond:

Capillary cone formation, bond force

|

Tail at 1st bond:

Wire break & feed of wire-clamp

|

|

Free Ball Size: Wand flame off power, time, swing repeatability,

|

|

15. Wire-Bond Quality

Data

15.1 Pull Test, Per MIL-STD-883

|

Non-Destructive

Pull Test.

(some % of wire quantity)

|

Wire size, mil

|

Alum,

Gram force

|

Gold,

Gram force

|

|

0.7

|

1.2

|

1.6

|

|

1.0

|

2.0

|

2.4

|

|

Destructive Pull Test.

(Wires are on coupons)

|

0.7

|

1.5 min.

|

2.5 min.

|

|

1.0

|

2.5 min.

|

3.0 min.

|

15.2

Bond Deformation, per MIL-STD-883

|

|

No device shall be acceptable that exhibits

|

|

Inspect

|

Ball bond

|

Wedge bond

|

|

bonds on die, substrate or package post

|

Method 2017.6

3.1.4.1. a

… the ball bond diameter is less than 2.0 time or

greater than 5.0 times

the wire diameter

|

Method 2017.6

3.1.4.2.a Re: Alum wire

… less than 1.2 times or greater than 2.5 times the wire diameter in width,

or less than 1.5 times or greater than 5.0 times the wire diameter in length

3.1.4.2.b Re: Gold wire

… less than 1.5 times or greater than 3.0 times the wire diameter in width,

or less than 1.5 times or greater than 5.0 times the wire diameter in length

3.1.4.4.g Re: tail

exceed 2 wire diameters in length at

bonding pad or

4 wire diameters in length at the package post or

10 mils

|

16. Glob Top Encapsulation

|

Epoxy,

Loctite

|

Glob top

|

Application

|

|

shape

|

size in

terms of

Wire-bond

area (L x W)

|

|

#349

|

High

viscosity

|

Round

dome

|

L + 30

mil x 2;

W+ 30 mil

x 2

|

Where

total thickness is

Not a

concern

|

|

#363

|

Low

viscosity

|

Odd dome

or “X”

shaped dome

|

L + 80

mil x 2;

W+ 80 mil

x 2

|

Where

total thickness is

demanded

as low as possible (<20 mil)

|

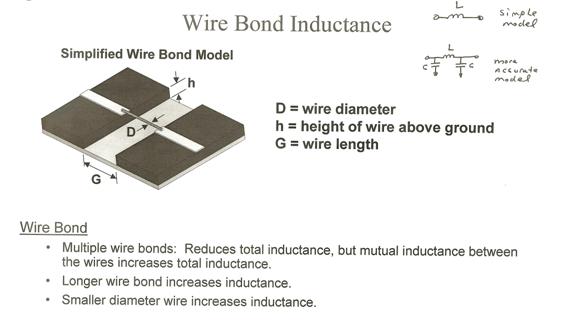

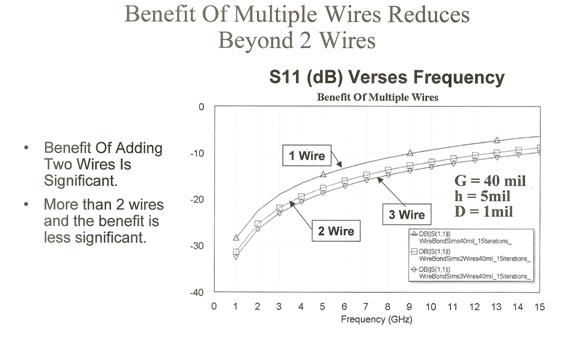

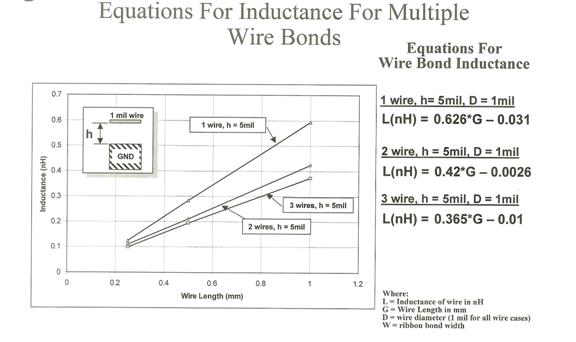

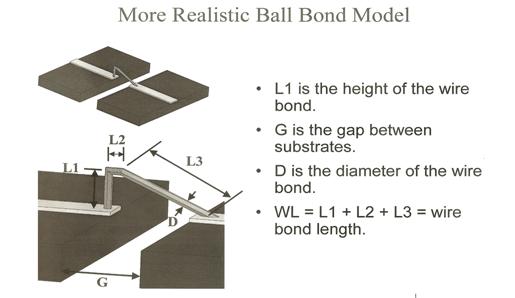

17. Principles of Wire Inductance

18. Inductance of 2 wires

19. Wire Inductance Calculation,

Simplified

20. Wire Length for Inductance

Concern

21. Wire Inductance Table &

Calculation, Realistic

|